DNA Extraction, 40.000 samples per day!

To meet the demands of processing a substantial number of samples per day, there is a need to develop an efficient DNA extraction system that offers high throughput rates. A collaboration between Synchron Lab Automation and Festo to realize this challenge has yielded impressive results, empowering customers in the seed industry to extract DNA from up to 40,000 samples daily.

However, to further enhance the process, there is a need to address the labor-intensive washing and waiting steps. Additionally, the management of microtitre plates and disposable tips requires an optimized system to ensure seamless operations. Therefore, a solution must be devised to minimize processing time and maximize sample throughput, allowing for a faster and more efficient DNA extraction process.

The DNA Factory: Meeting High Throughput Demands in the Agricultural Industry

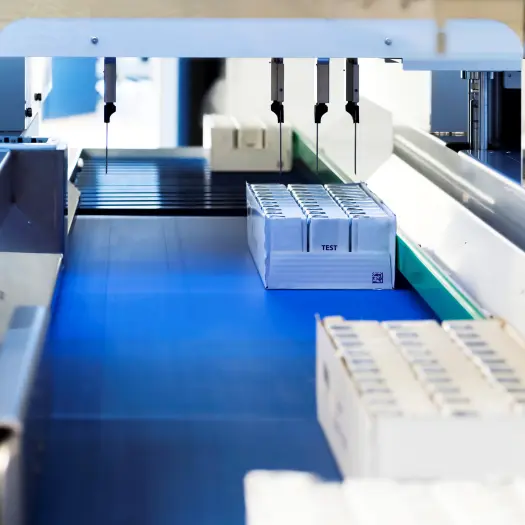

In the agricultural industry's plant breeding processes, a machine is utilized to extract DNA from shredded plant material. Throughout the extraction phases, key functions are carried out by essential components provided by Festo. The workflow commences with a holder capable of accommodating up to 400 microwell plates, where 200 plates serve as input and 200 as output.

To streamline the process, an initial step involves the bar code reader SBSI scanning all the microwell plates at the beginning of each run. This information is crucial for subsequent identification and transport. Electric axes EGC, in combination with a semi-rotary drive DRRD and a gripper DHPS, efficiently handle the microwell plates. These plates are placed on carriers that move seamlessly through various stations on a dedicated transport system.

Next, a rinsing phase takes place to separate the DNA from other materials. Metal micro-spheres are introduced, with the DNA selectively attaching itself to these spheres while the remaining material floats up within the microwell plates. The process involves the addition and extraction of liquid at multiple washing stations. To facilitate this, the pipetting head is lowered using an electric slide EGSC. After rinsing, the microwell plates retain clean DNA, which is then transported via the same system to the final processing step: DNA extraction.

During the extraction phase, the responsibility of handling the pipetting head for DNA extraction lies with electric axes EGC, in conjunction with an electric slide EGSL. Each microwell plate contains 96 samples, and the entire process from start to finish takes approximately twenty minutes. To maintain a continuous workflow, a new plate is initiated every 2.5 minutes, ensuring efficient and timely extraction of DNA samples.

IF WE CAN THINK IT, WE CAN BUILD IT

Discover Your Possibilities

Upgrade your laboratory workflows with advanced automation in DNA extraction. Contact us now to learn more and unleash the full potential of streamlined sample handling.

Key Features

Top to bottom airflow

PlateFeeder

Barcode Scanning

Magnetic Bead Extraction

10 x 96 Channel Heads

Microwell Plate Holder

Rinsing Capability

Specifications

Perfomance Specifications

| Throughput Approx. | 40,000 |

| Plate Capacity | 400 microwell plates |

| Reagents | 10 x 96 channel heads |

| Processing Time

| 20 min per plate |

| Integrated Shaker | ? |

| Pump Control | ? |

| Smart Camera | ? |

| Input Specifications | ? |